Winches and winch systems

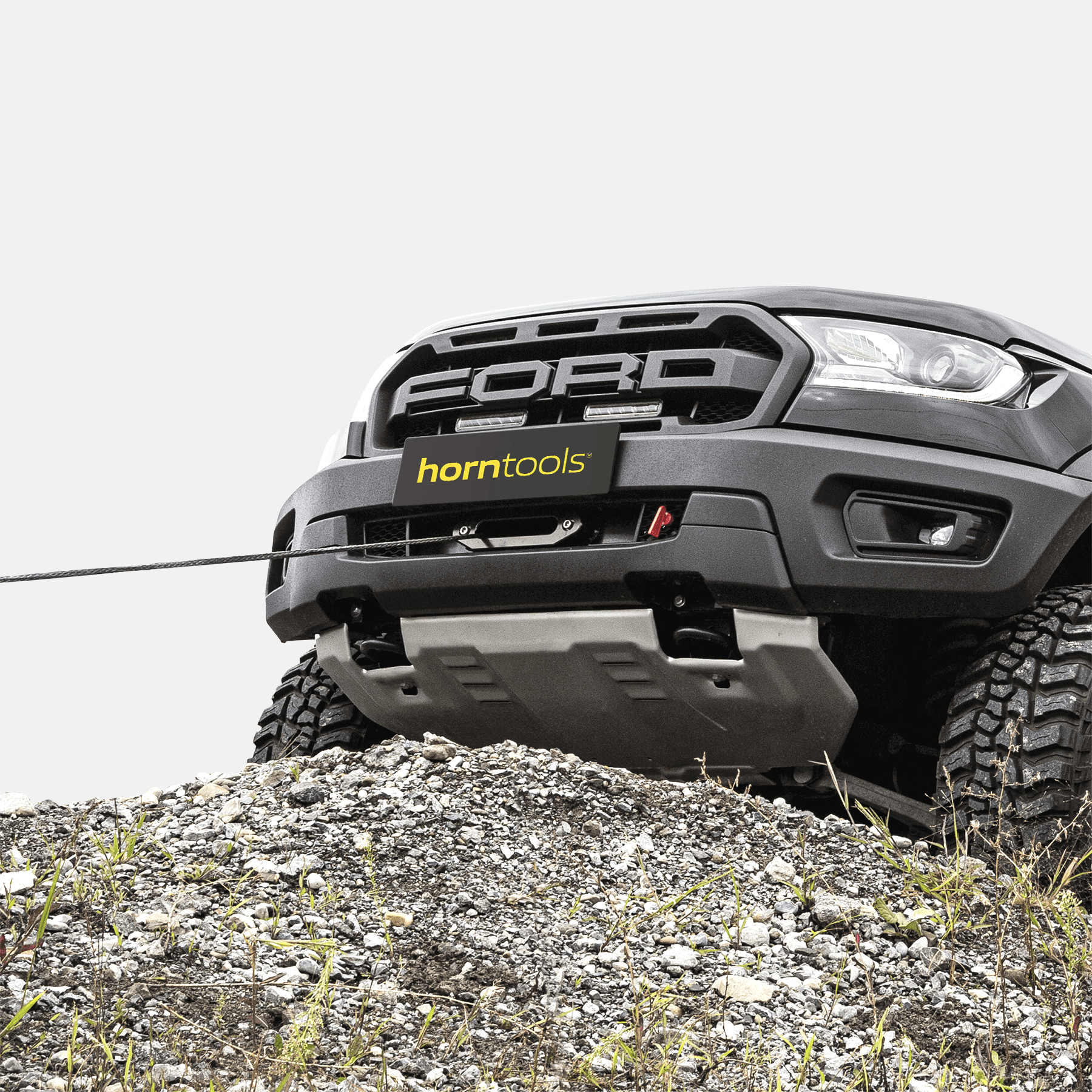

Electric winches & winch systems with pulling power from 2.5 to 8 tons. Suitable for Ford Ranger, Suzuki Jimny, Toyota Hilux, Land Rover Defender, Mitsubishi L200, Nissan Navara, VW Amarok, Isuzu D-Max, Fiat Fullback, Lada Niva Taiga and many other vehicles.

Unsure which winch is the right one?

Are you unsure which winch is right for your purpose? Then find out with our winch quiz:

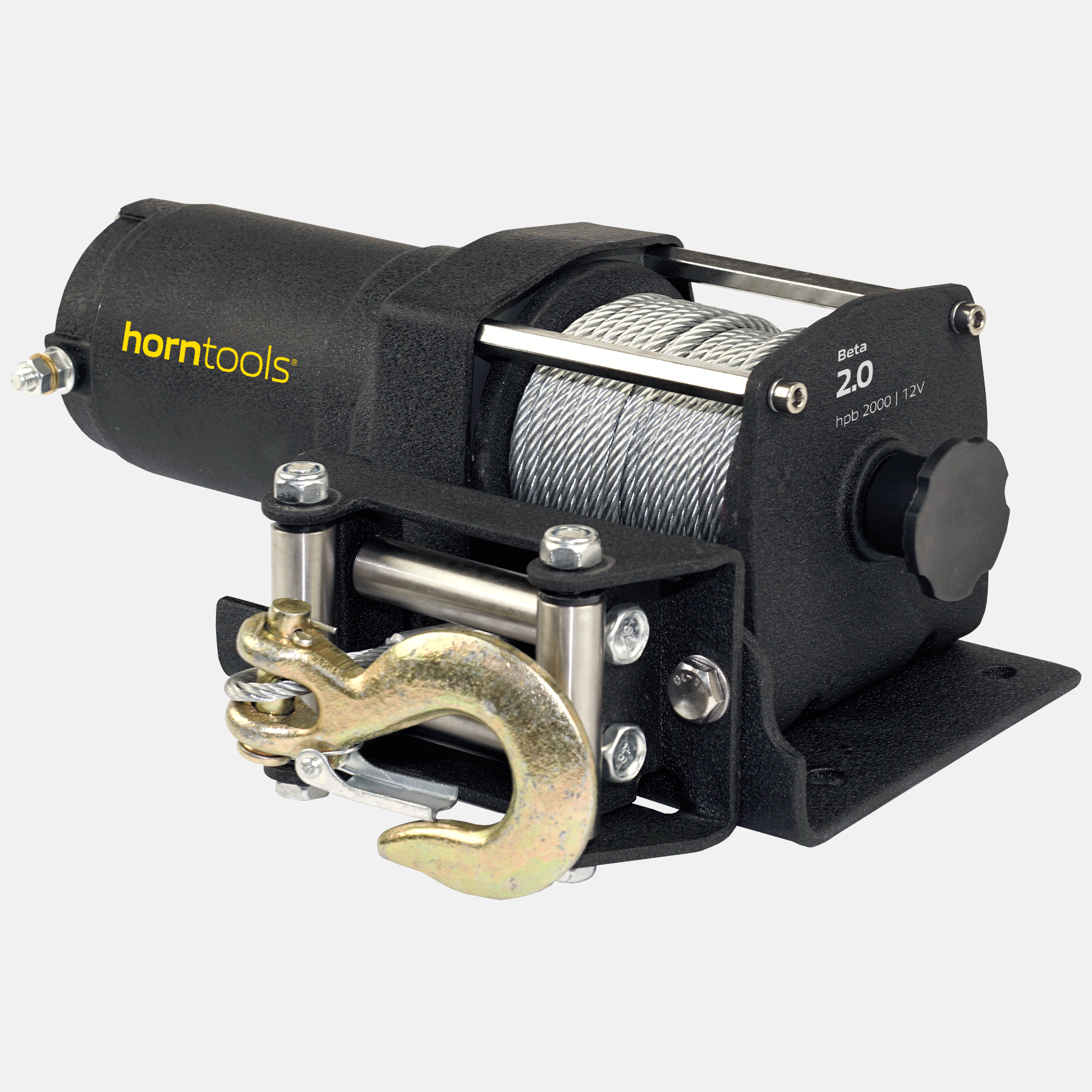

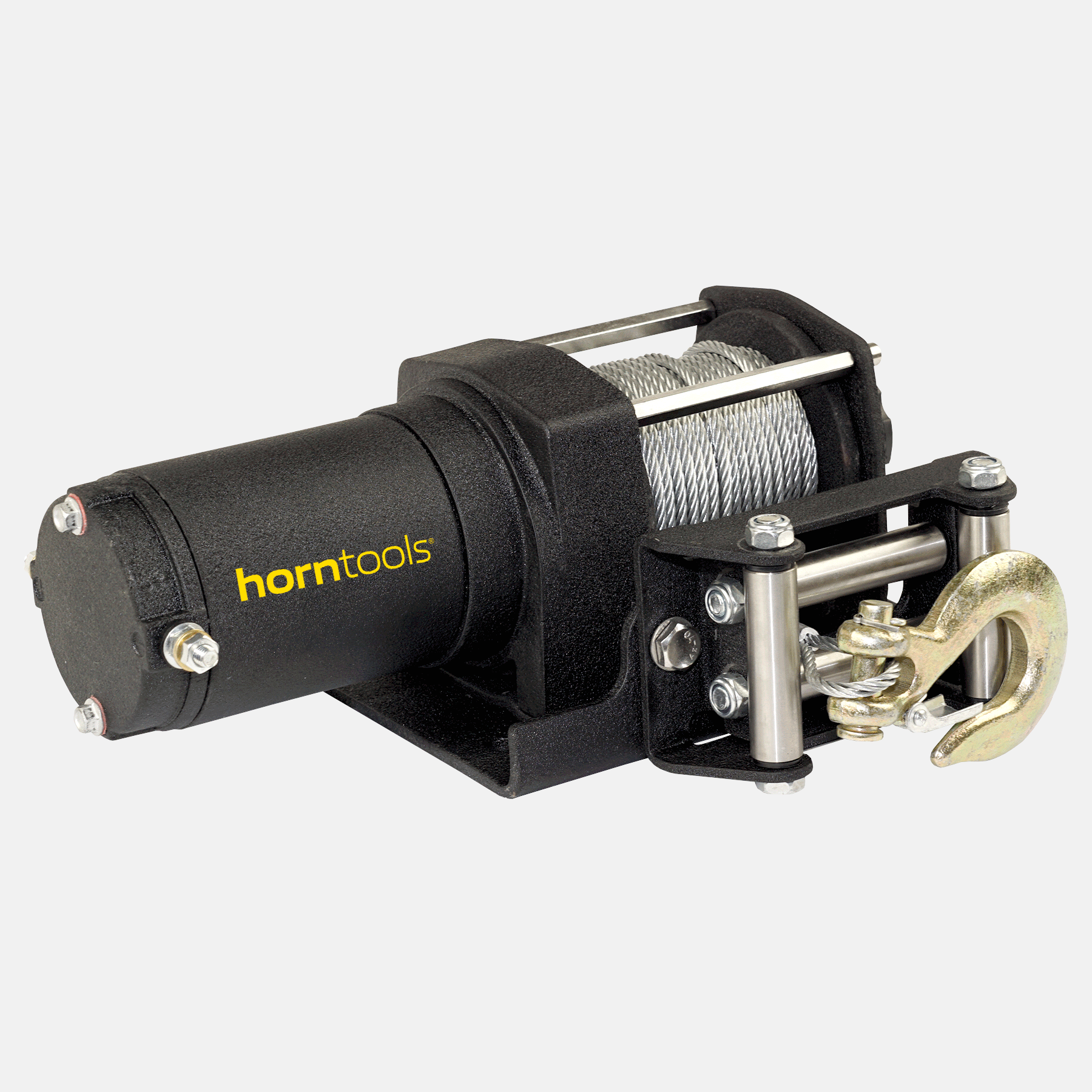

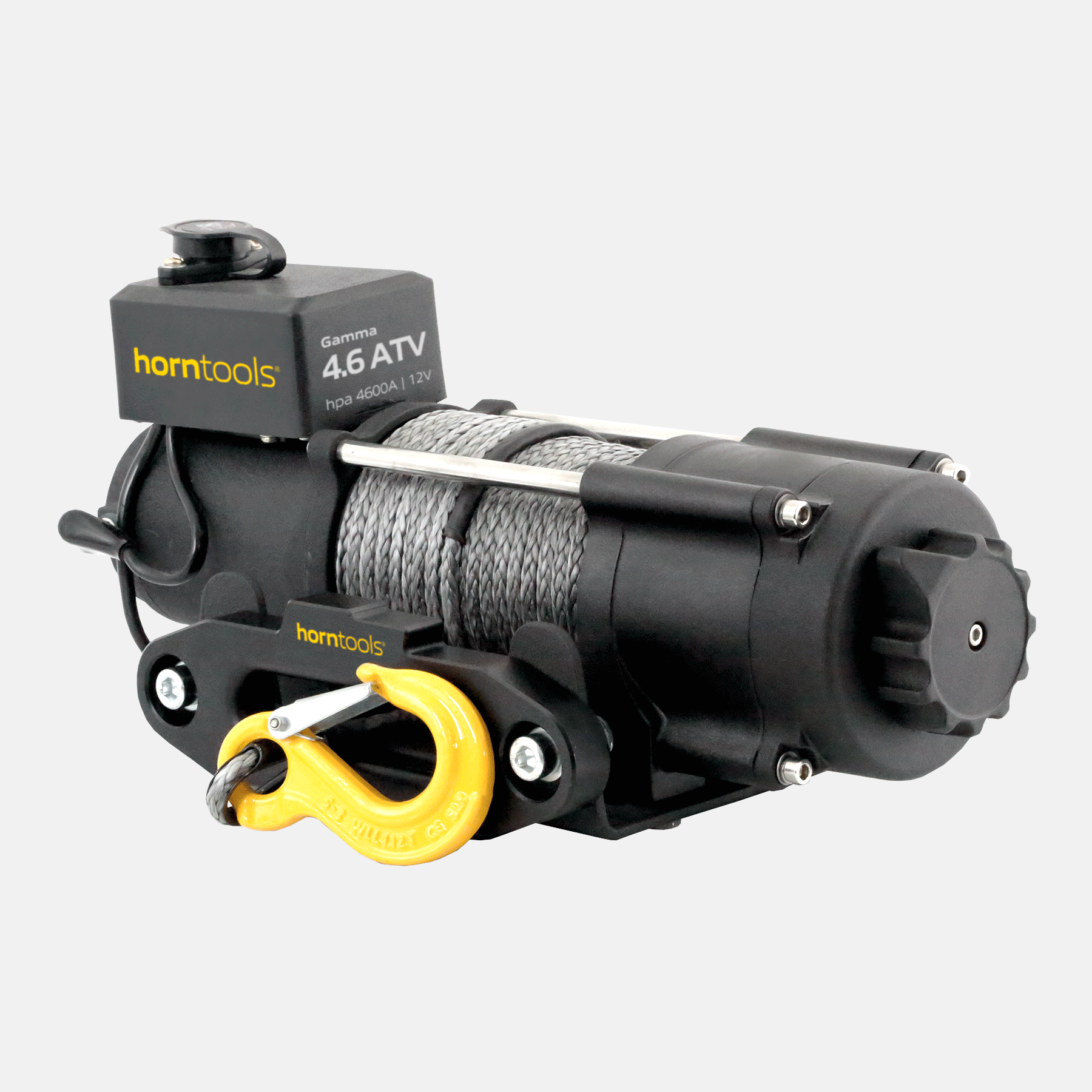

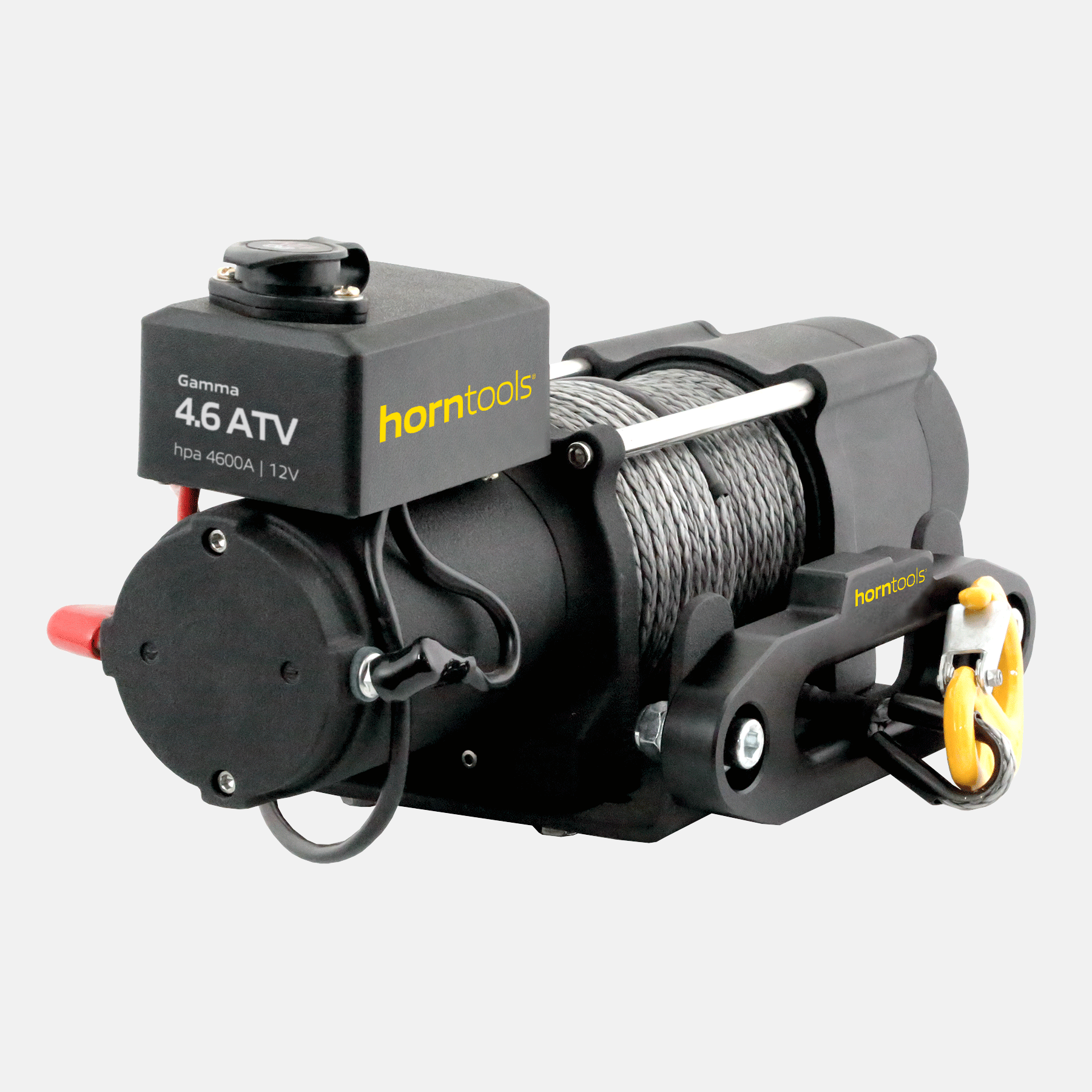

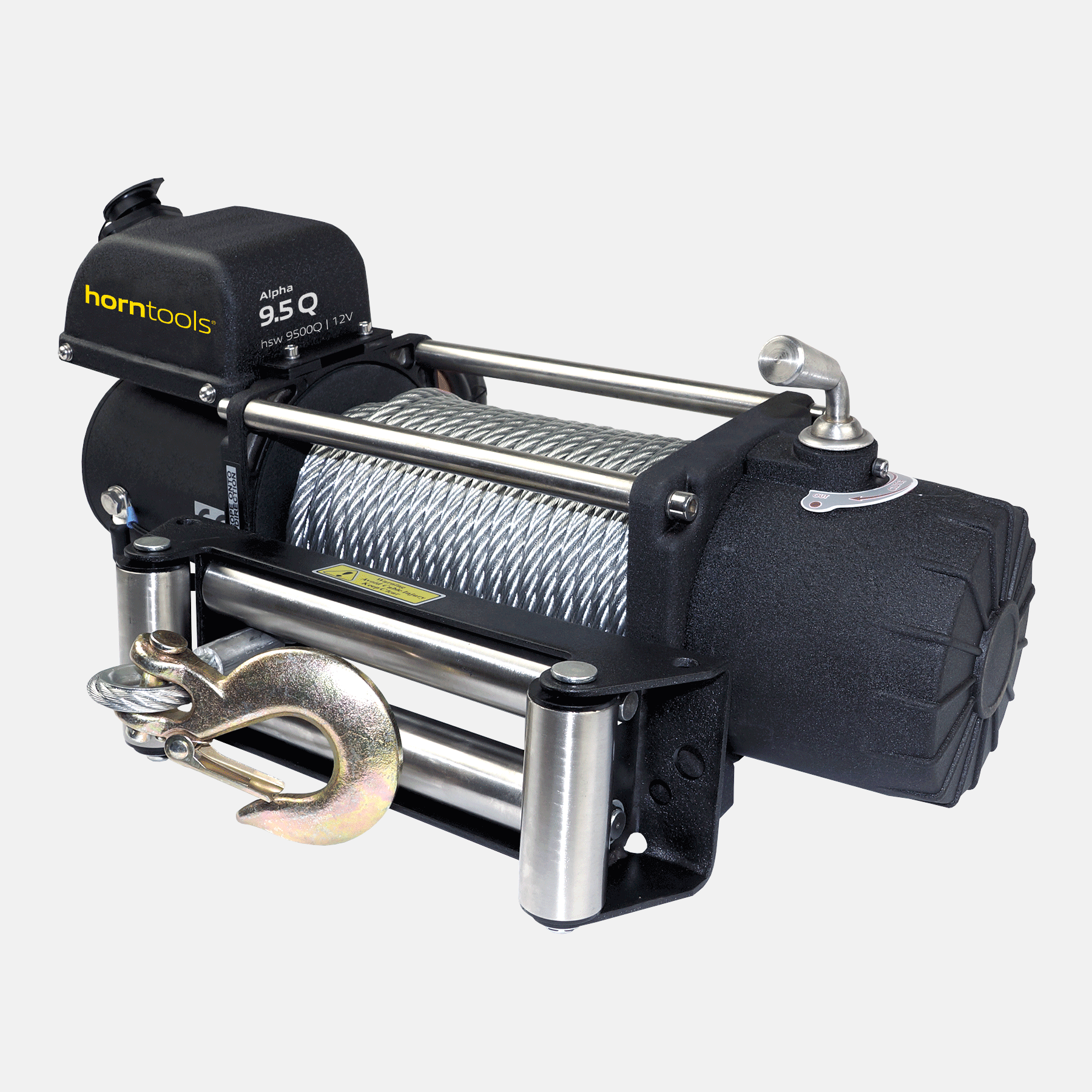

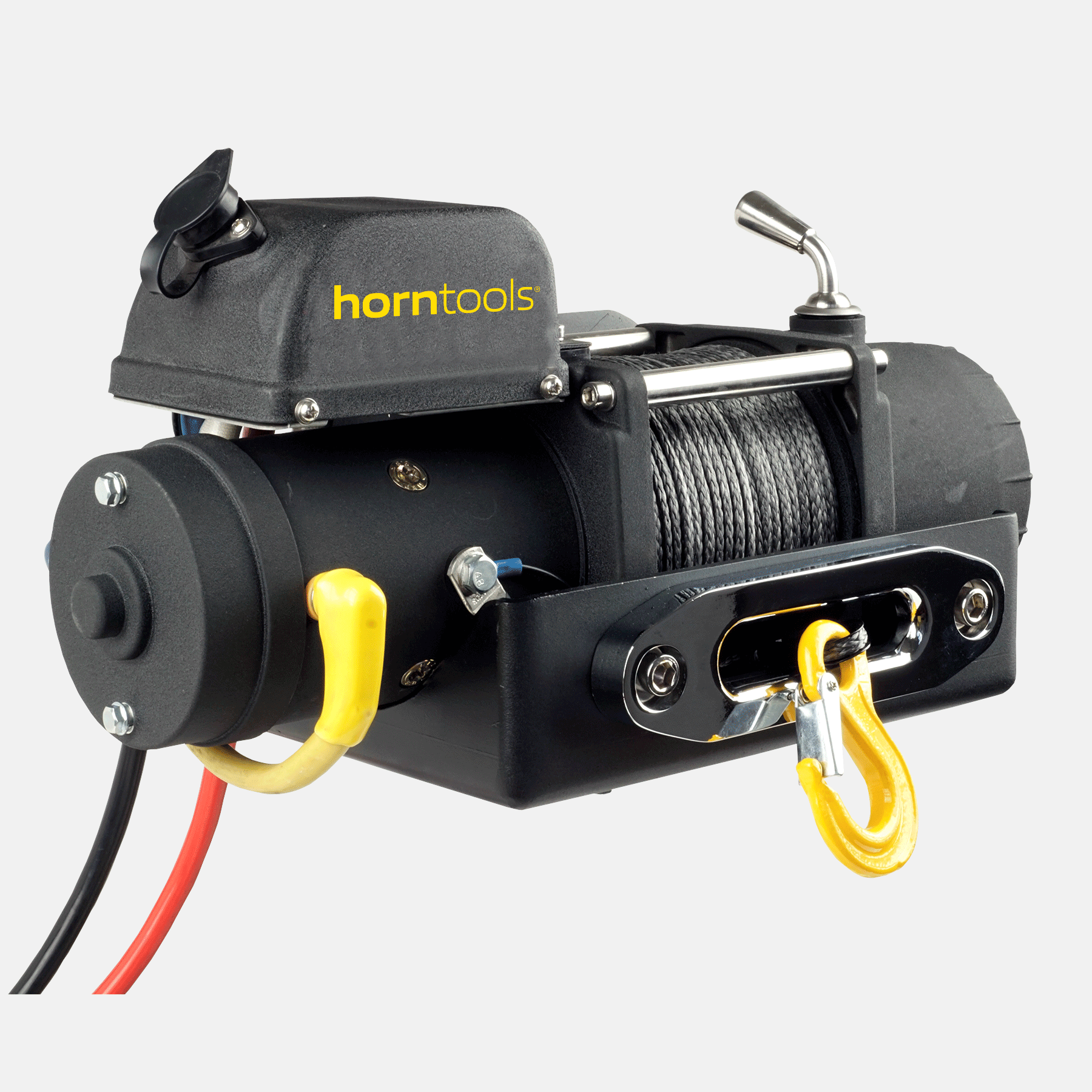

Bestseller winches

horntools winches are characterized by their variety and quality, which guarantees a long service life and functionality even under the most difficult conditions. We have the necessary spare parts for all winches in stock, so we can always help you.

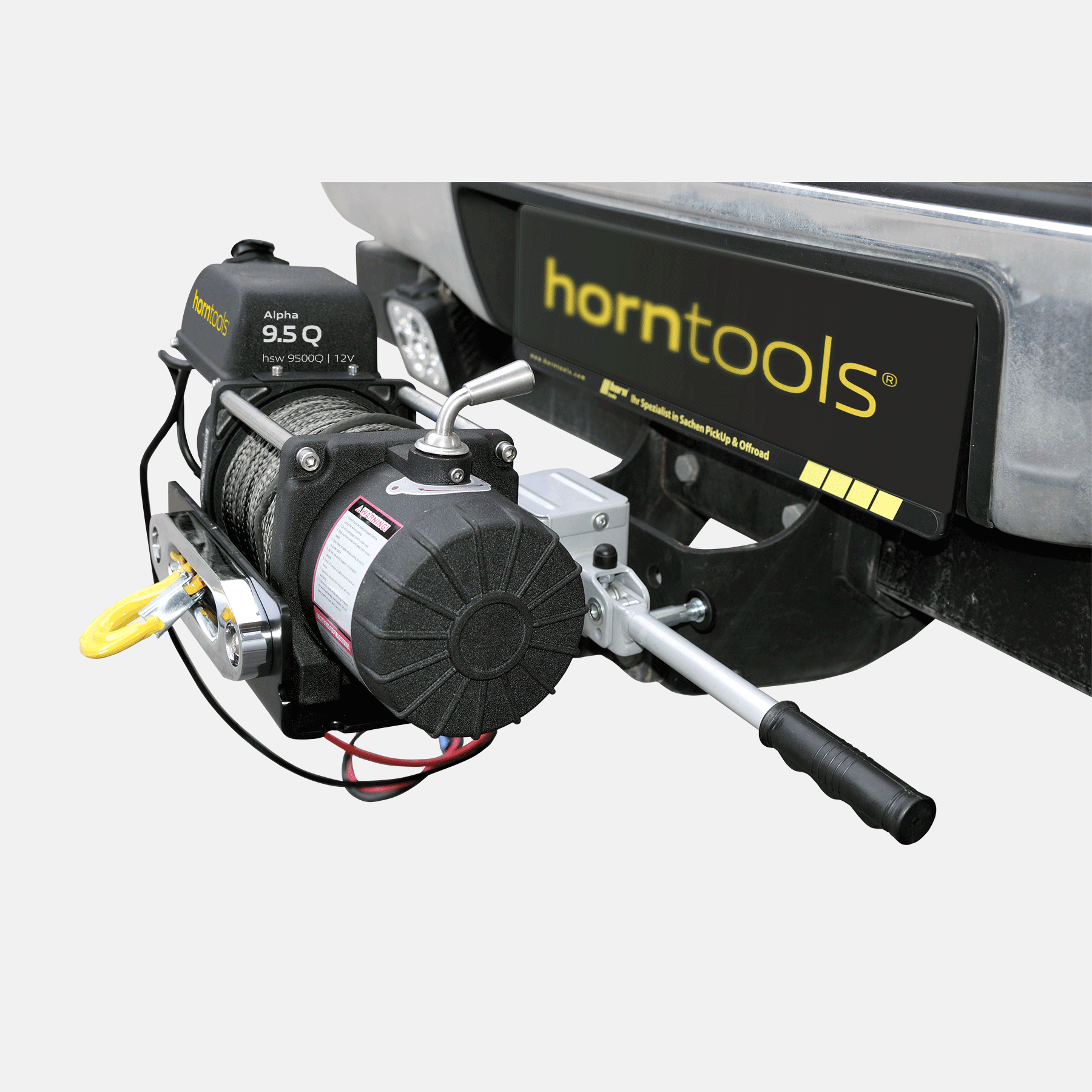

Bestseller winch systems

We also offer our winches directly in finished installation systems. All complete with parts certificate or ABE (general operating permit). We work closely with TÜV Austria so that you can get the system registered. We offer systems for various vehicle models such as Suzuki Jimny, Toyota Hilux, Land Rover Defender or Ford Ranger.

Bestseller winch accessories

In addition to the winches, we also have a wide range of accessories such as snatch blocks, soft shackles, kinetic ropes and much more in stock.

Why winches from horntools

Why should you buy horntools winches with 12V or 24V? The electric winch is often used for self-recovery in off-road areas, heavy work in forestry, agriculture or in the construction industry. An electric winch can be mounted virtually anywhere: on the trailer, on the trailer hitch or on the vehicle (4x4, Jeep, tractor, small tractor, ATV, SUV, quad, etc.). You can find the right electric winch in our online shop at horntools.com. Our customer service is also always available by phone and email and will be happy to advise you on all aspects of winches. horntools stands for high-quality winches. We also offer spare parts for all winches, guaranteeing not only high quality but also longevity.

What types of winches are there?

The main difference between 12V and 24V electric winches is the voltage at which they operate. This tension significantly influences the performance and possible uses of the winches.

12V winches:

12V winches are typically used for use as a winch in cars, SUVs, all types of off-road vehicles and other vehicles with a 12-volt battery. They are widely available and readily available, making them a popular choice for many off-road enthusiasts. These winches are easy to install and can be connected directly to the vehicle battery. 12V winches are ideal for lighter tasks such as pulling vehicles out of mud or sand, but they have their limitations when it comes to moving heavy loads or operating in extremely demanding terrain. At horntools you will find a large selection of 12 volt electric winches. As always with an excellent price-performance ratio.

24V winches:

24V winches work at a higher voltage and are therefore able to generate more power. They are commonly used in heavier commercial vehicles, trucks, military vehicles and industrial applications. Because of their higher tension, they can tow heavier loads and are more suitable for use in extreme off-road conditions. However, 24V winches are not as widely available as 12V winches due to their specific electrical system requirements and require special installation and possibly additional electrical adjustments to the vehicle.

Overall, the choice between a 12V and a 24V winch depends on the specific needs of the user and the vehicle in which it is to be installed. It is important to choose the correct tension according to the intended use and individual needs to ensure optimal performance and efficiency of the winch.

Hoist winch or pull winch?

Hoist winches are intended for lifting loads, pulling winches for pulling loads to the ground (e.g. self-recovery in off-road areas). horntools only sells pulling winches. Our winches are not approved for lifting loads!

Do I need a remote control?

A radio remote control, i.e. a remote control for the winch without a cable, is a practical addition. Basically, all winches come with a remote control (with cable). The radio remote control allows you, for example, to operate the winch from the car or from further away. In our range, you will find various compatible radio remote controls for your winch.

How strong should a forestry winch be?

The exact answer, of course, depends on the exact use: Are you pulling wood on a slope, how thick is the wood being pulled by the forestry winch, and how often do you carry out the forestry work? In order to cover all possible areas of application and not to push the winch to its load limit, we recommend using a 4.5 ton forestry winch. Our Alpha models are very versatile and can be ordered with steel cable or synthetic cable.

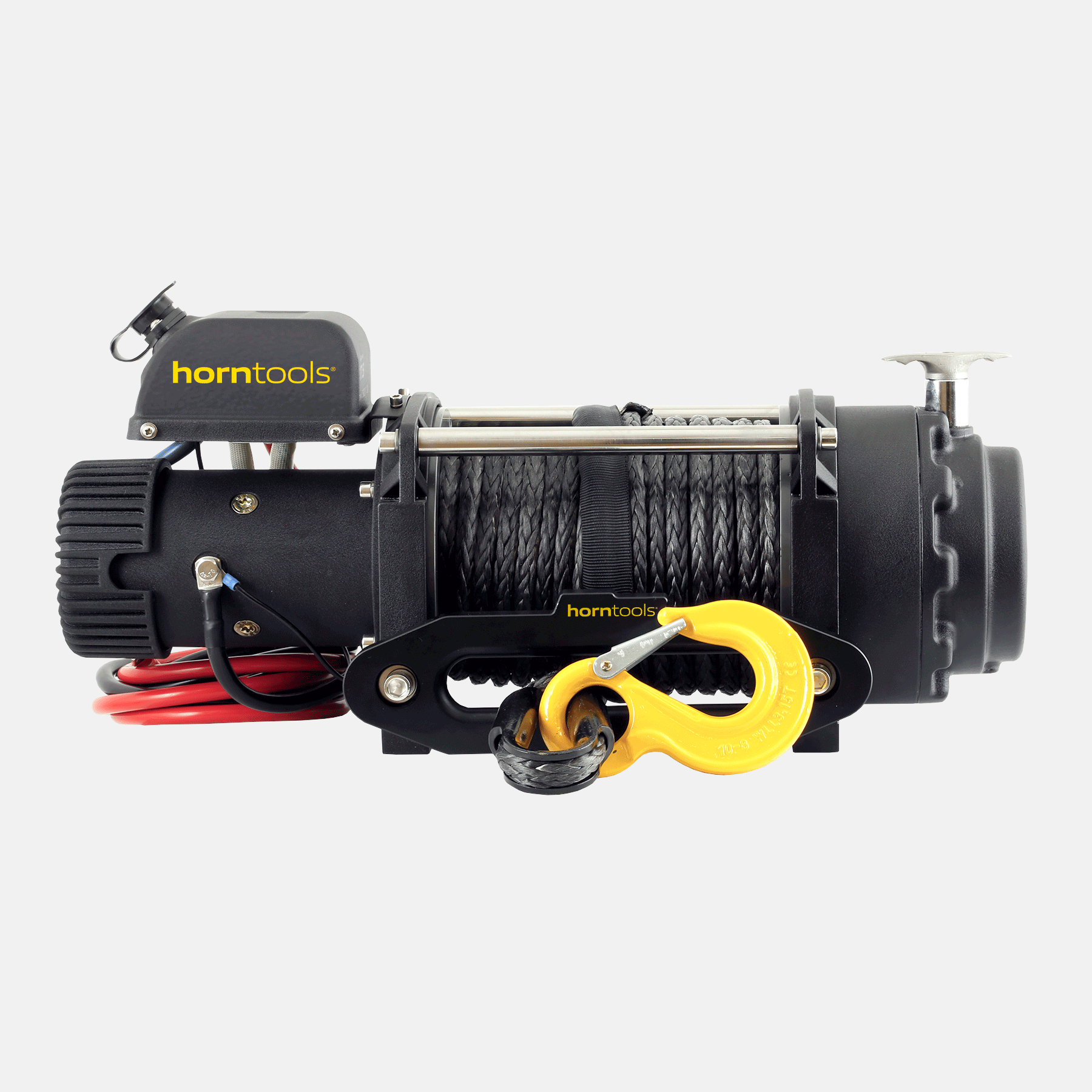

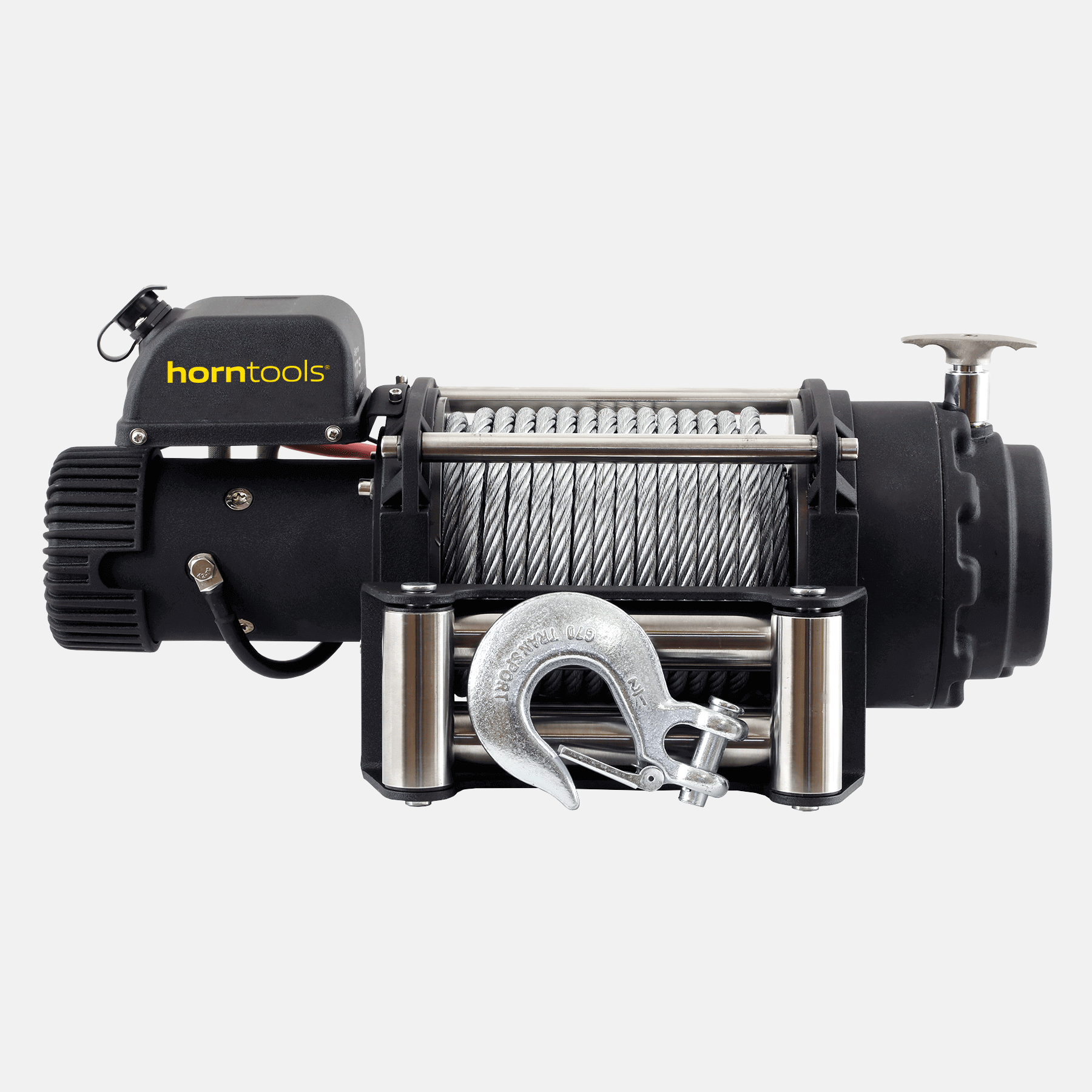

Synthetic rope or steel cable? Advantages and disadvantages

Synthetic ropes have been on the rise in recent years - and rightly so. The old fear that synthetic ropes would not withstand the load has long been a thing of the past. In principle, it can be assumed that synthetic ropes and steel ropes with the same rope diameter can withstand approximately the same tensile force.

At first glance, the strengths of the synthetic rope are certainly its weight; the rope is approx. 4.5 times lighter than a conventional steel rope. Furthermore, a synthetic rope cannot rust, has no protruding strands in the event of damage (risk of injury), does not whip so extremely when it breaks, has hardly any spring effect (the rope does not pull itself together when laid down) and damage to the rope is easier to detect.

However, synthetic ropes also have disadvantages: Synthetic ropes are more sensitive in comparison and chafe more easily. Instead of rust, the rope is affected by UV radiation; it is also much more sensitive to heat, which can have a negative effect especially when the rope drum heats up (continuous operation).

The steel rope is generally more resistant than a synthetic rope, but damage to the rope is more difficult to detect (internal strand breaks). Corrosion is also an issue with steel ropes.